Electrodialysis Application

Colloidal Silica Manufacture

Phase Transfer Catalysts Manufacture

Desalination of fruit juice

Removal of tartaric acid from wineDesalination of pharma / chemical intermediates

Desalination of cheese whey

Desalination of soy sauce

Production of amino acids from amino acid salts

Desalination of starch sugar, soybean saccharide, xylose and xylito desalination

Acid recovery from stainless steel pickling effluent

Recovery of electroplating solutions

Production of acid and alkali from inorganic salts/industrial waste streams

Acid recovery of aluminum foil pickling process

Production of organic acid from organic acid salt

Production of amino acids from amino acid salts.

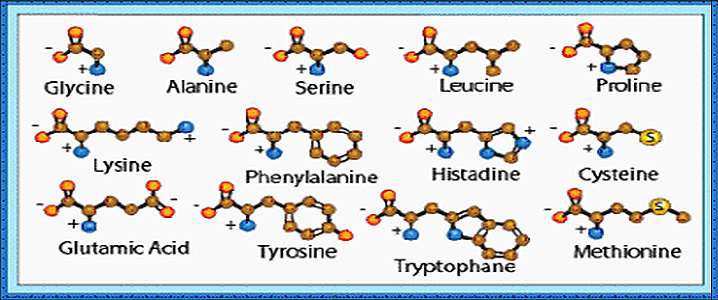

Electrodialysis is used to remove NaCl from the mother liquid for separation of Amino acids. This not only increases the yield of Amino acid but also reduces the cost of waste water treatment & disposal. Since Amino acids are amphoteric electrolytes having carboxylic acid and amino groups in the molecule, their loss during Electrodialysis can be minimised by adjusting the pH value of the feed to the iso-electric point of the amino acid. Desalination of Phenylananine, Amino Glycerin, Threonine, Lysine, 4-Hydroxy Butyrate, Hydroxyphenylglycine, Amino Butyric Acid, Tryptophan, Arginine, Glutamine, Glutamate, Glycine, Cystine, Leucine, Aspartame, Fumarate, Serine and so on.

Threonine desalination:

The Original process using ion exchange resins is replaced by Electrodialysis. The feed material contains about 2%-3% salt, suspended solids, proteins and saccharides. Ultrafiltration prior to ED is recommended.

Phenylananine desalination:

The Original process using ion exchange resins is replaced by Electrodialysis. The feed material contains about 2%-3% Phenylananine, about 2.5% inorganic salt, proteins and pigments.