Electrodialysis Application

Colloidal Silica Manufacture

Phase Transfer Catalysts Manufacture

Desalination of fruit juice

Removal of tartaric acid from wineDesalination of pharma / chemical intermediates

Desalination of cheese whey

Desalination of soy sauce

Production of amino acids from amino acid salts

Desalination of starch sugar, soybean saccharide, xylose and xylito desalination

Acid recovery from stainless steel pickling effluent

Recovery of electroplating solutions

Production of acid and alkali from inorganic salts/industrial waste streams

Acid recovery of aluminum foil pickling process

Production of organic acid from organic acid salt

Recovery of electroplating solutions.

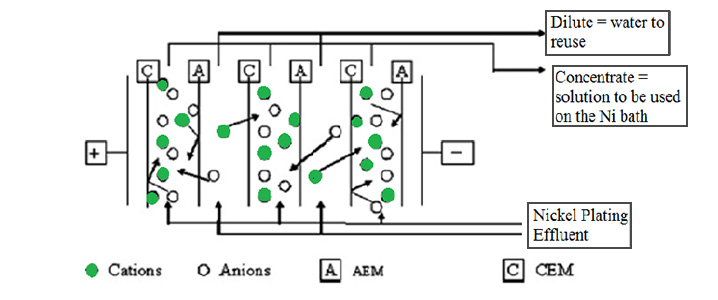

Electrodialysis Stacks for cost effective recovery and reuse of nickel electroplating solutions from Bright Nickel electroplating effluent are available. Electrodialysis is a clean technique able to produce dilute and concentrated solutions from a contaminated started solution.

The treated effluent had sufficient quality for reuse as rinsewater in galvanic process. All ions detected presented adequate concentrations for reuse. Even the organic compounds from the additives could be removed by ED.

Electrodialysis can be applied effectively for chromium recovery from chromium electroplating drag-out for reuse. Electrodialysis effectively recovers more than 80 percent of plating metals such as nickel, chromium, cadmium, copper and zinc.

Recovery of EDTA from electroless copper plating bath.

Recovery of exhausted alkali from process solutions for the manufacture of nickel-cadmium batteries.